Introduction

With the rapid development of face recognition technology, the days when 2D cameras dominated image processing are gone. Nowadays, 3D camera technology is widely used to photograph objects with a three-dimensional structure and perform in-depth processing. Particularly, 3D structure, namely wave of light structure, is one of the most widely-used technology in many machine vision systems.

What is The 3D Structure Light Technology?

3D structured light technology is widely used in smartphones, digital cameras, housing design, and industrial fields. They have three main features to solve various needs in different industries:

How Does It Work?

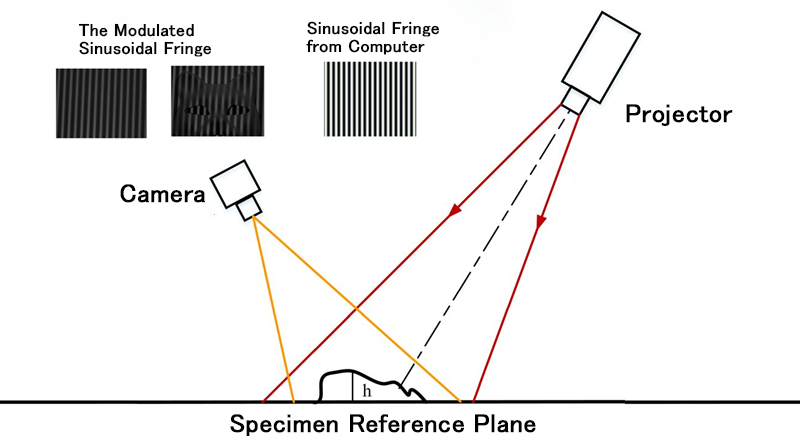

the hardware of 3D structured light technology is mainly composed of a camera and projector. Structured light is the active structural information projected onto the surface of the measured object through the projector, such as laser stripes, grey codes, sinusoidal stripes, etc; Then, a structured light image is obtained by capturing the measured surface with single or multiple cameras; Finally, based on the principle of triangulation, the three-dimensional reconstruction is realized through the three-dimensional analysis and calculation of the image.

A 3D structured light camera can be divided into two main types: Line scanning structured light camera and Area scanning structured light camera.

Area Scanning Structured Light Camera

Area array structured light can be roughly divided into two categories: random structured light and coded structured light. Random structured light is simpler and more commonly used. By projecting point-like structured light with uneven brightness and random distribution into the measured space, a binocular camera will capture an image. Then, the obtained binocular image is subjected to epipolar correction. Through binocular dense matching, the corresponding binocular depth map image can be reconstructed for further measurement.

Line Scanning Structured Light Camera

Compared with the area-array structured light camera, a line-scan structured light camera is simpler and more accurate. It is widely used in the field of object volume measurement and 3D imaging in the industry. Theoretically speaking, while a moving light source scans the object slowly, the camera records the corresponding scanning process. Then, according to the relative pose and camera internal parameters of the camera and the light source in this process, the three-dimensional structure of the object to be measured can be reconstructed.

In comparison, the random array of structured light is the most commonly used in the 3D reconstruction. By projecting random structured lights into the surface alongside binocular dense reconstruction, our machine vision system is capable to obtain more reliable and accurate results than using RGB images to construct 3D images alone.

What Are The Advantages of 3D Structured Light Technology?

There are a lot of advantages of using structured light lasers for 3D imaging. First, when the imaging environment remains unchanged and the ambient light is minimized, a 3D structured light camera can produce highly accurate results with ultra-high resolution, allowing our system to capture high-quality images to determine the dimensions of the object.

Second, the speed. Structured light lasers are usually fast, its speed to create 3D imaging is almost as fast as capturing images. The complicated algorithms can quickly determine the size of objects, thus effectively accelerating the detection process and improving production efficiency.

Last but not least, as long as the distance is fixed, a 3D structured light camera always obtains a better measurement coverage area than other 3D imaging techniques. This proves that the 3D structured light technology is especially useful for larger parts that need multiple scans, further saving time and creating efficiencies in production.

In summary, 3D imaging has been rapidly and widely used in different industries. The development of intelligent image sensors and other technologies continues to expand the ability of 3D imaging in industrial applications.

SmartMore Inside is a one-stop smart manufacturing platform integrating hardware, software and solutions. We provide full chain products including machine vision products, measurement sensors and systems, centre control products, robotics, and 3D technologies for industrial automation. Interested in learning how SmartMore can assist click here to learn more!

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent