Many industries rely on machine vision cameras to ensure the quality of parts during machining and production because of the precise nature of the equipment needed to perform job roles. Small electrical components need exact measurements to conform to the current technology. The same is true for other industries like the precision component machining, medicine production, vehicle, and electronics, where the products must have as few defects as possible.

Defect Detection plays a fundamental and important role in the supply chain. More specifically, it ensures the quality of your end products, reducing the release of poorly-made or defective products from reaching the market. That is the most obvious benefit which lets the companies avoid lowering their brand value and market reach and the risk of a damaging outcome. What’s more, it reflects the reasons why defects are made so that the engineers can precisely adjust the production machines to solve the problems, cutting the repairing and maintenance costs.

When this data is run through an advanced optimization system, it provides critical information for detecting the defective products and preventing them from making further down production lines. This is even more critical in the case of projects or parts that may be dangerous, like batteries, precise parts, and liquid foods and medicines.

2 Ways to Detect Defects

The most common methods of defect detection include:

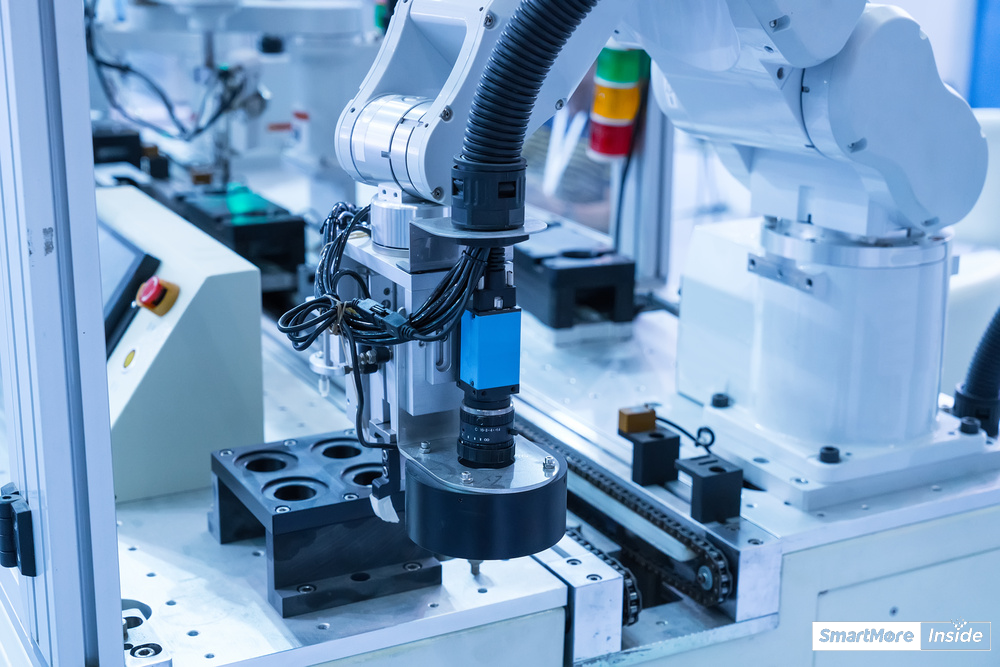

The combination of advanced algorithms and high-resolution images is leading to increased efficiencies and capabilities in defect detection. Machine vision cameras automatically detect the specifications of the object in real-time and output clear images with enough definition for an industrial PC to analyze.

A good machine vision camera is the basic condition for completing perfect defect detection. Without its powerful ability to capture every detail of the objects, it loses significance in analyzing all the data since they are not accurate enough.

The more accurate the detected result, the higher the quality assurance control. State-of-the-art machine vision cameras ensure the accuracy and flaw-exposure of every image they output. They help companies maintain standards set by third-party oversight organizations that offer certifications or confirm precise measurements of parts to reassure public interest.

Machine vision cameras are used in many ways to ensure the overall QA requirements of products and parts moving through production lines. This is achieved through:

This detects scratches and other visual imperfections like over/undersized parts that may not meet the standards or expectations of the client. A scratch on something as small as a bolt in a car could lead to dangerous outcomes if that nut comes loose while driving. That is why precise lighting is used to capture high-resolution images through high frame rates. The result is an incredible image with exceptional per-pixel precision, so all details are reviewable.

This system then analyzes the captured information and compares it to standards set by your team or a third-party organization. As the machine vision camera is used more often, it can begin to adjust to new situations based on historical data.

Every piece of data is finally converted to digital format and stored for future use. The act of archiving alone is a really big challenge since the massive volume of data is being processed at such incredible speed.

When you are in the market for quality-made machine vision cameras by a trusted industrial camera manufacturer, consider our expert team at SmartMoreInside. We offer a wide variety of industrial high-speed cameras that owns the following features; thus, they can improve your manufacturing and machining process to secure more client business and trust.

With more than 20 years of in-depth research-based innovation in the industry, we have the experience you need to succeed. We have intensively worked with clients from all kinds of industries that rely on our products to ensure a safe and accurate part during production every time. Our team understands the challenges a slow production line can have on a business and work hard to help alleviate that concern with our specialized camera products.

Feel free to explore our storefront and reach out to our professional support experts with any questions you may have. Thank you for considering the expertly built machine vision cameras from SmartMoreInside.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent