Wafers are known as the “crown jewels” of the semiconductor industry.

Yield rate is the most important indicator of wafer production, which directly determines the cost and capacity of wafer manufacturing. However, accidents always occur in the traditional production process due to the old instrumentation and inefficient manual monitoring of readings, which also raises the cost and risk of error correction.

In response to this pain point in the pan-semiconductor industry, SmartMore has found a new solution for the wafer manufacturer, which is minimal but helpful. Manufacturers only need to install the SMore ViMo box equipped with ViMo’s intelligent industrial platform on the original equipment, thus resolving the problem without replacing the old equipment with new expensive ones.

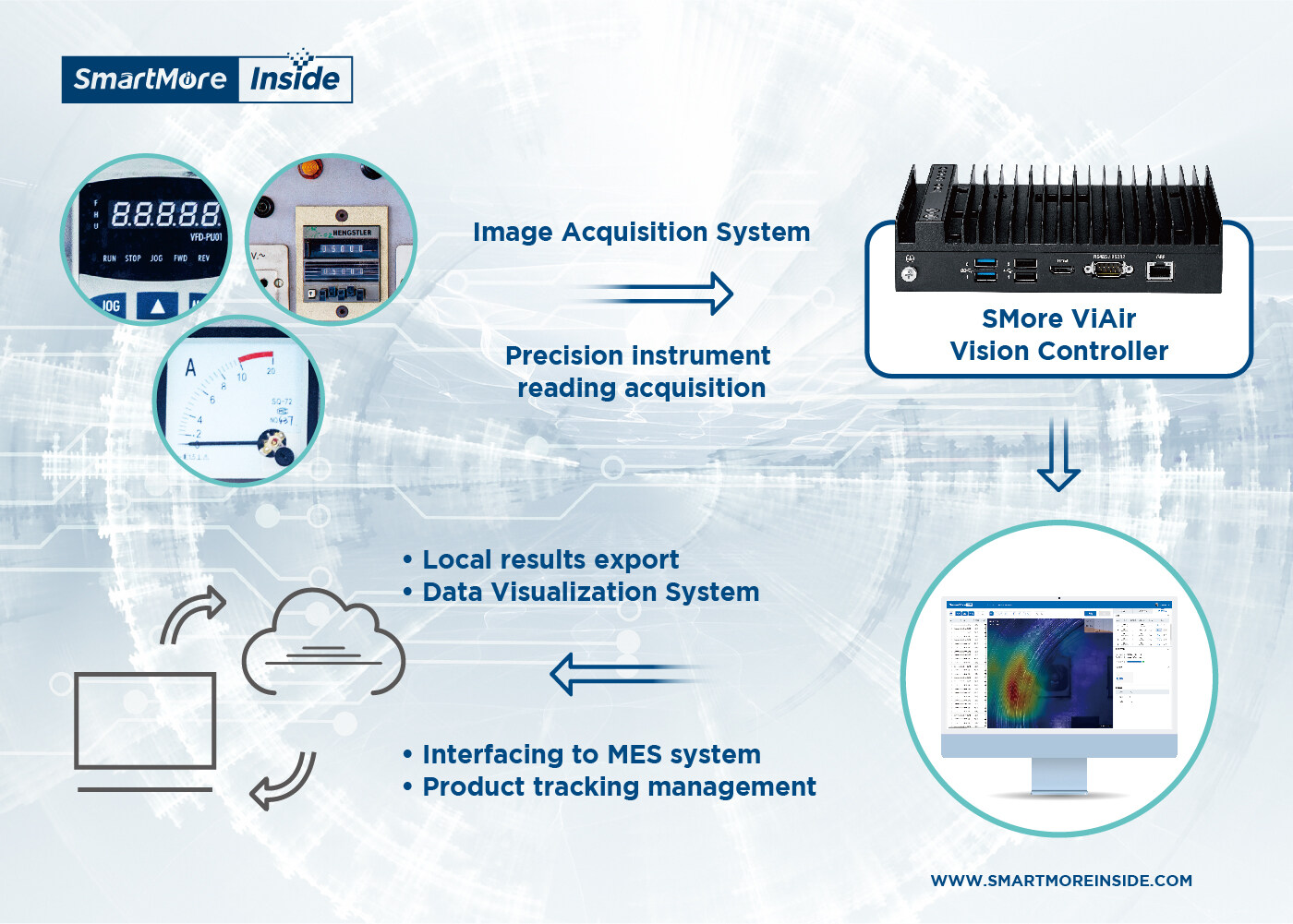

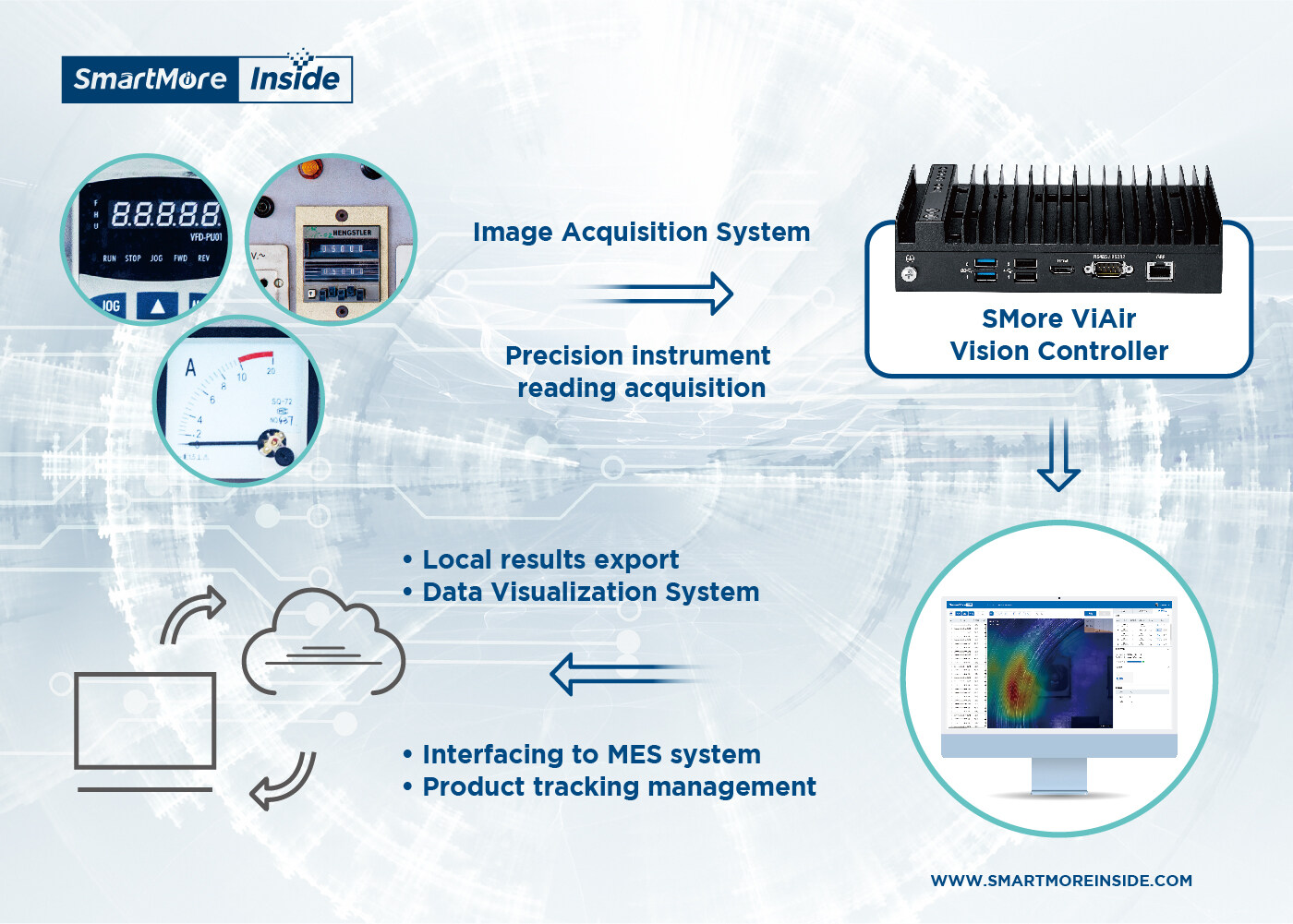

SMore ViMo solution is to utilize the surveillance cameras to collect data and video images from the instrumentation’s screen, then the ViMo “Smart Black Box '' carries out real-time detection of the analyzed data, so as to realize the timely alert and the warning function of the parameters. The vision controller can be seamlessly connected to the SMore ViLab industrial software platform which can import real-time data into the company's own management system (MES/SPC), and then generate data reports for operators. This solution enabling the fabricator to manage the shop floor and discover fault points whilst increasing efficiency, on the other hand, the fabricator is able to have a complete picture of the dynamics of each parameter, which facilitates the traceability of historical data and the analysis of process indicators, which is of great significance for process improvement in the pan-semiconductor industry.

Intelligent upgrade of data collection not only requires the efficient improvement of the data accuracy in depth but also the effective reduction of cost in breadth.The wafer manufacturer used to take care of data only from 20 machines per person before applying ViMo solution, now it is possible for every operator to monitor more than 500 machines at one time. Based on ViMo's powerful computing capability, each ViAir Smart Box can drive and analyze at least four surveillance cameras at the same time; and the price of the box is much lower than the cost of the intelligent equipment with the same level of computing capability and functions.

As a high energy-consuming industry, semiconductors have long been criticized for their high demand for electricity. According to statistics, TSMC's global production plants totally consumed 14.33 billion kWh of energy in 2019, equivalent to the annual residential consumption of electricity in Shenzhen that year. The use of SMore ViMo can provide IoT-based data collection of various traditional meters in semiconductor plants, real-time monitoring of various energy consumption and electrical data, real-time grasp of electricity consumption load, and effective control and management of energy consumption and carbon emissions, which is conducive to the achievement of the double reduction goal of energy saving and carbon reduction.

Intelligent upgrade is not a quick fix. Unlike many head manufacturers, a large number of enterprises have a long history of old and non-intelligent equipment, it is not universally applicable for a costly global intelligence upgrade. Therefore, intelligent OCR precision recognition of complex scenarios is of great value to the pan-semiconductor industry. SMore ViMo can customize and install the “smart eye” to match its function, enabling the whole production process to realize agility and resilience from shop floor production to lab monitoring in any scenario where image acquisition is possible.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent