As algorithms and AIs become ever more embedded in people's daily lives, we are liable to unleash the holistic potentiality of robots and try to have them doing mostly everything for us. But, do you really know what collaborative robots are and what kinds of future they will lead us to...Let's take a look.

Collaborative robots, namely, are a type of robots that can collaborate with people in the workplace shoulder to shoulder, making automation easier than ever before for businesses, even for SMEs (small and mid-sized enterprise) around the world. It helps to take charge of strenuous and dangerous production steps for human beings for the sake of their safety. Collaborative robots are known for optimizing the process as well as driving productivity efficiently. And they can be employed in a wide range of various settings, including machine tending, assembly, welding, buffing, and many more.

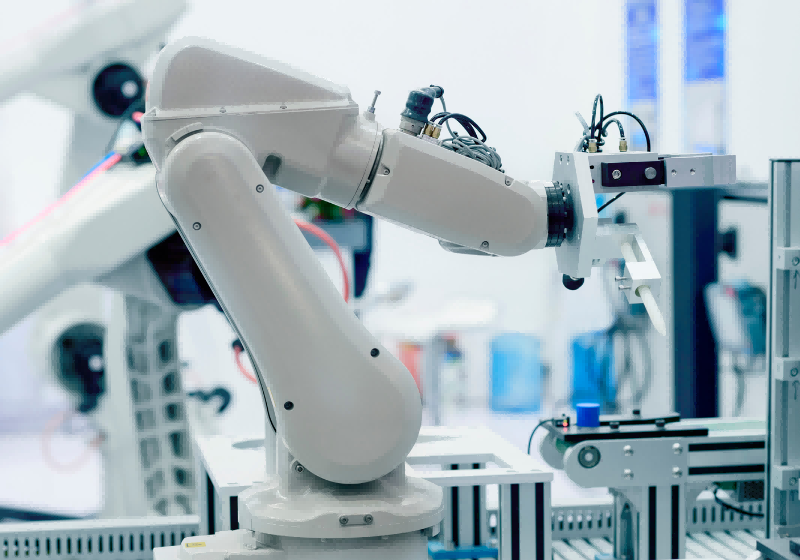

In recent years, faced with a formidable pandemic that has been wreaking havoc around the globe and aggravated increase of aging population, more and more enterprises and organizations of all walks of life are proactively seeking feasible automation solutions to deal with labor shortage and low efficiency. Nowadays, the industrial robot on a worldwide basis is riding on a freeway, especially the market in China which witnesses a 58% of growth rate and becomes the largest robot market in the world for consecutive 5 years. From the field of automobile, metal processing, 3C manufacturing to home appliances, food packaging, application of collaborative robots continues to expand and new business opportunities come out non-stop.

Speaking of industrial robot, it is comprised of traditional industrial robot and collaborative robot. Then what's the edge of collaborative robot over traditional one? Traditional robot features high cost, difficult to maneuver, and unable to team up with human beings. They have to work in isolation and relevant worker cannot flexibly manage the machines so none of effective artificial interventions will take place in the face of an emergency. While the appearance of collaborative robot brings decisive transformation to industrial production and manufacturing. For example:

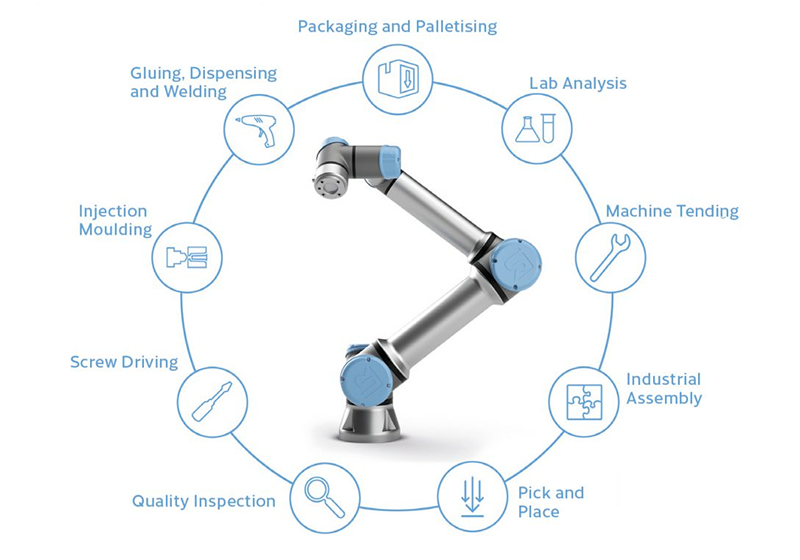

Based on the advantages of human-robot collaboration and in line with market demand, more flexible collaborative robots have become a feasible solution to undertake assembly and extraction work. It can maximize the advantages of humans and robots, allowing robots to better cooperate with workers and adapt to a wider range of work challenges. And some common applications are as follows:

Manual picking and placing should be one of today's repetitive tasks for workers. Boring operations can easily lead to manual mistakes and physical fatigue and injury. In actual production, this operation can be used to pick up items from pallets or conveyor belts for packaging or sorting. Pick-and-place cobots require an end-effector to grab objects, which can be a gripper or a vacuum chuck device.

It requires workers to stand in front of CNC machine tools, injection molding machines, or other similar equipment for long periods to keep an eye on machine operation needs. This process is time-consuming and extremely tedious for the operator. In this case, the use of collaborative robots not only frees employees, but also can simultaneously maintain multiple machines to increase productivity.

Manual fashioning operations require the use of hand tools. Vibrations caused by the tool can result in operator injury. Types of fashioning work that cobots can perform include polishing, grinding, and burring. Cobots can complete corresponding actions through manual instruction or computer programming. The built-in control system makes the robot more durable. Through the end effector or the built-in force sensing device, the fashioning of parts of different size can be realized.

Finally, collaborative robots can also perform quality inspections on parts. Fixing multiple high-resolution cameras on the collaborative robot can automate the quality inspection process and obtain inspection results quickly. Using collaborative robots for inspection can achieve high-quality outcome and more accurate production batches.

Conclusion

Before, people may wonder how to produce more in a fast-paced environment? How to lower the cost while not affect quality...With an increasingly growing desire to deploy automation at the workplace and have human-machine collaboration to improve work accuracy, cobot will be a key game changer for the next generation. In the end, if you’re looking for cobots that can work alongside your people as their robotic colleagues, a Smartmore Inside cobot could be the ideal solution for your business. With 20-odd years of experience delving into machine vision and like, SmartMoreInside has developed a wide range of prime quality offerings, which gains plenty of acclaim worldwide. So what are you still waiting for? Come get in touch with one of our cobot experts to discuss your needs today. For more information, click here.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent