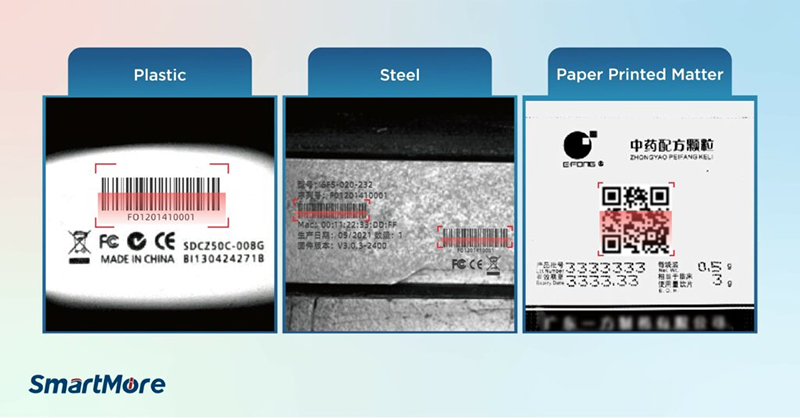

SmartMore has collaborated with numerous manufacturers in terms of scanning solutions. The ability to deploy barcode scanners in manufacturing as an integrated part of the process is something we view as a consistent gain for these organizations. Most organizations utilize barcodes as a means of product identification and traceability in their manufacturing line's automatic sorting technology. During printing or manual labeling, issues like printing errors, missing barcodes, and duplicated codes are unavoidable.

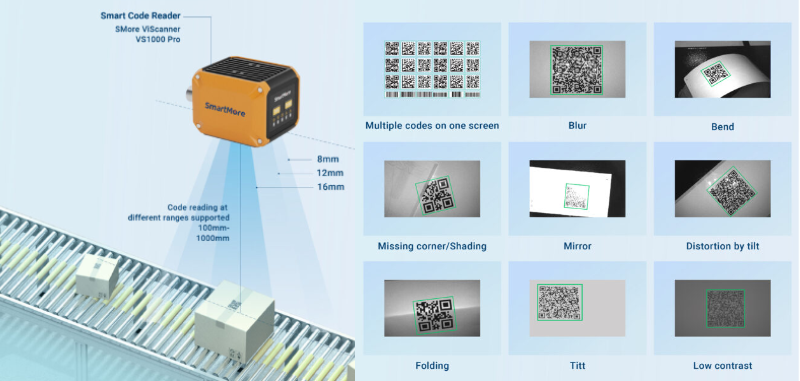

Manual sorting is rife with flaws such as high work intensity, higher error rate, expensive, and reduced efficacy. Instead of relying on human labor, modern organizations have accepted the need for the best barcode scanners to increase production efficiency and solve the problem of self-service barcode detection on conveyor belts and assembly lines for achieving production line automation.

A barcode system prevents errors in any corporation by making the manufacturing process faster and more efficient than ever before. The use of scanners for code reading not only saves your time but also minimizes the costs and human efforts with efficacy. Barcode technology is no longer limited to large corporations. It is accessible and cheap to businesses of all sizes. Any organization may profit from a barcode system with adequate preparation.

Barcode reading applications are critical to:

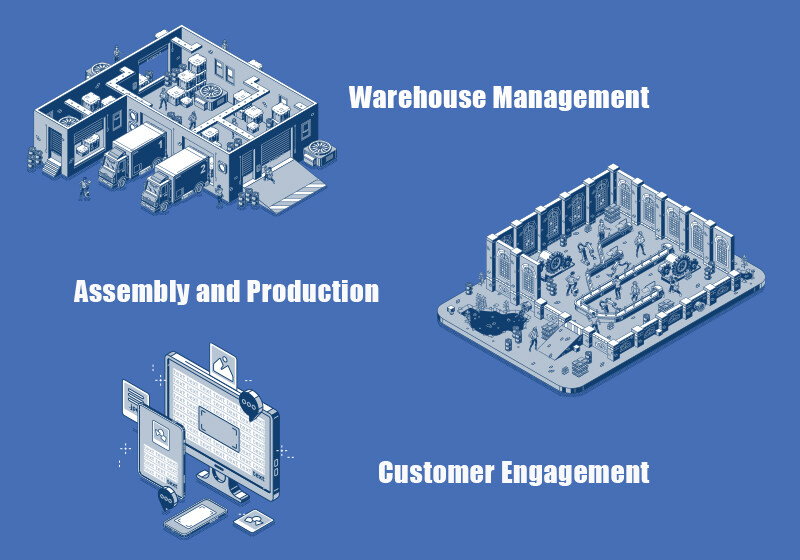

So where can we use this smart technology? There are many areas, including:

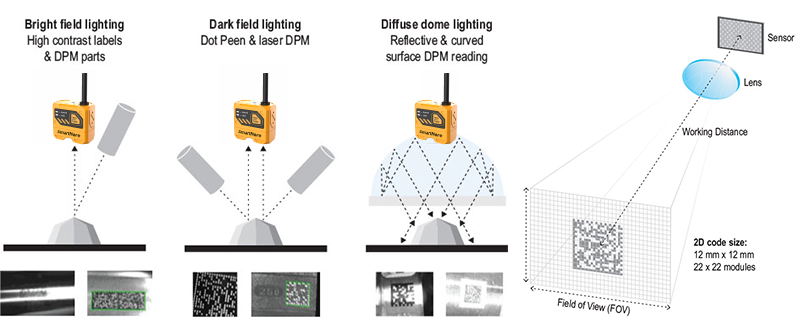

SMore ViScanner is a highly smart image-based barcode reader that is equipped with a high-performance intelligent chip by which data collection speed can reach 60fps; it adopts an automatic mechanical focusing method, which can adapt to the working scenarios of 100-1000 mm code reading. It can work in a harsh environment with exceptional performance. They reliably read damaged, distorted, blurred, scratched, and low-contrast codes. They are suited for the most demanding industrial applications due to their customizable options, ease of setup, and speedy deployment.

When to adopt a barcoding system is mostly determined by the organization based on their needs and technological benefits. Not just demand for completing the orders on time with no delays generates a need of using these scanners but it became an integral part of each industry for production and supply chain procedures because the speed and accuracy you get by using these scanners cannot be achieved through other means. Therefore, Smore ViScanners has earned a repute across the globe because it not only solves the manufacturing problems but also increased the pace of work with high productivity.

The application of SMore ViSacanners is broad, Barcodes are used in almost every industry (i.e., semiconductor, electronics, automotive, FMCG, Medicine, etc., etc.) to automate and simplify traceability by tracking everything from where something was produced and when it was shipped, to which retailer sold the product, at what time, and for how much. Governments throughout the world have begun to mandate medical devices and pharmaceutical producers to use machine-readable codes on every packaging, down to individual medicine containers, in recent years. Our devices connect processes, people, and products from warehouse to assembly line, to field maintenance and customers. Smore ViScanners can be deployed almost in every process for example Retail (Procurement, Inventory Management, Point of Sale, Sales Force Empowerment), Logistics (Pickup and Delivery, Field Service), Entertainment (Ticketing), Automotive (VIN Scanning), Manufacturers (Parts Tracking, Inventory Management, Field Service), Healthcare (Vaccine Production, Pharmacy Applications), Government (Document Tracking, Asset Tracking), etc., etc. To know more details about our ViScanner barcoding technology and its implication please visit our website below.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent