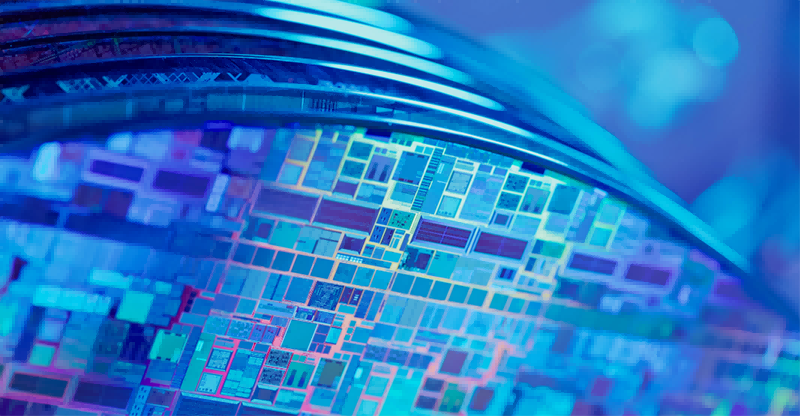

Wafers are known as the “crown jewels” of the semiconductor industry. Being the most crucial raw material for chip set production, wafer can be regarded as a victory highland for competitions among great powers and a solid foundation for digital economy. The process of chip set production is like building up a house, of which wafers are the base. It is extremely pivotal that one layer must be laid completely flat after one another. That is to say, it has strict rules to produce wafers and meanwhile the technique is of a great deal of difficulty.

In order to meet up with the high standard of realizing chip set functionality, wafers must be endowed with high crystal purity, ultra-high flatness, excellent surface cleanness and zero impurity. Traditionally, wafer manufacturers would hinge on manual detection. However, accidents always occur in the old-fashioned production process because of obsolete industrial facilities and insufficient manual detection of minimal defects, which raises the cost of labor and error corrections.

So how to ensure the quality of silicon wafers and prevent undesirable items from getting to next stage become a pin spot where a solution is badly needed in the pan-semiconductor industry.

Solution

SMore Vimo is a set of end-to-end AI solution applied for industrial setting. With its full name “Vision Inspection and More”, SMore Vimo can not only perform vision inspection but more. It mainly consists of two major system platforms: model training and model running, which can provide the full stack, one-stop and management capabilities for industrial manufacturing and create a standardized delivery system for intelligent manufacturing. Through the latest-generation vision AI technology, SMore Vimo is capable of handling a wide range of problems under complex scenarios, for instance, material tracking, defect location, workpiece counting, detection of cosmetic defects and many more. From data collection to online modeling and factory deployment, the integrated solution offered by SMore Vimo is widely applicable to various industries, like 3C electronics, semi-conductor, automotive, new-energy, logistics, food and so on.

4 core algorithms

With 20 years of delving into research of advanced technology, SmartMore provides 4 core vision algorithm capabilities for the industrial field, such as product diversification and fast product update cycle.

Adopt end-to-end solution based on technology precipitation, support single character and multi-character standard and recognition, which can recognize different background characters, such as steel print, laser engraving, printing, textile, etc. For semi-conductor industry, it is very hard to recognize and read characters printed on wafers because of dim lighting and reflections. SMore Vimo feature advanced algorithms developed specifically for wafer identification to help manufacturers in seeing clearer.

Locate and classify targets in the detected materials, applicable to multi-target detection, small target detection, counting, etc. SMore Vimo deep learning software performs automated defect screening on a much larger portion of wafers. Furthermore, trace defects ad record reasons, which greatly aids optimization of the whole technique process.

Classify and judge the detected objects. Such as OK/NG secondary classification judgment of materials, detection object color, 3C defect sub-classification and other issues. SMore Vimo deep learning tools help manufacturers identify and classify defects of silicon wafers.

Fine to pixel level detection and edge recognition of detection objects. Such as identifying cracked areas of silicon wafers, bruised areas of bearings, etc.

How does it work

SMore Vimo provides a complete closed loop from image collection to model upgrade and factory deployment. Then only three simple steps for users after deployment.

Through connecting Vimo with imaging equipment to get images, users can perform data labeling on Vimo platform

Users simply need to conduct parameter configuration according to the conditions of data labeling then realize “ modeling with one click”. After SMore Vimo processes model self-training, users can select the best and most fit output to carry out actual test.

After factory deployment, the AI model will continuously upgrade and optimize itself along with the production process so as to improve the accuracy and efficiency.

Conclusion

Whether it is large material or high-precision component, Vimo can precisely identify defects, which greatly ensures prime quality control. Meanwhile, it will conduct analysis of key factors to further improve yield rate and production technique. Since SMore Vimo made its debut on market, it has already helped several Top 500 enterprises in the manufacturing industry to realize smart manufacturing in different sections. The application of Vimo changes the production process from manual operation to delicate collaboration of AI operation and manual management, thus drastically elevate the efficiency and reduce cost of time and economy. If you interested, click here to get more information.

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent