The food and beverage sectors are under immense pressure to maximize equipment efficiency without forfeiting quality due to lean operations and narrow margins. To reduce interruption and reliably produce safer, high-quality goods that can be tracked throughout the supply chain, successful manufacturers use machine vision and barcode scanning technologies. SmartMoreInside technologies enable food and beverage businesses to tackle some of the most difficult inspection, verification, and tracking applications by offering the most comprehensive variety of machine vision systems and barcode readers.

Companies that produce food and beverages must assure food safety, risk management, traceability, assembly verification, and product quality inspection. SmartMoreInside is helping businesses with innovative machine vision and barcode devices to achieve higher productivity and less waste and defects.

SmartMoreInside machine vision can help boost your operations

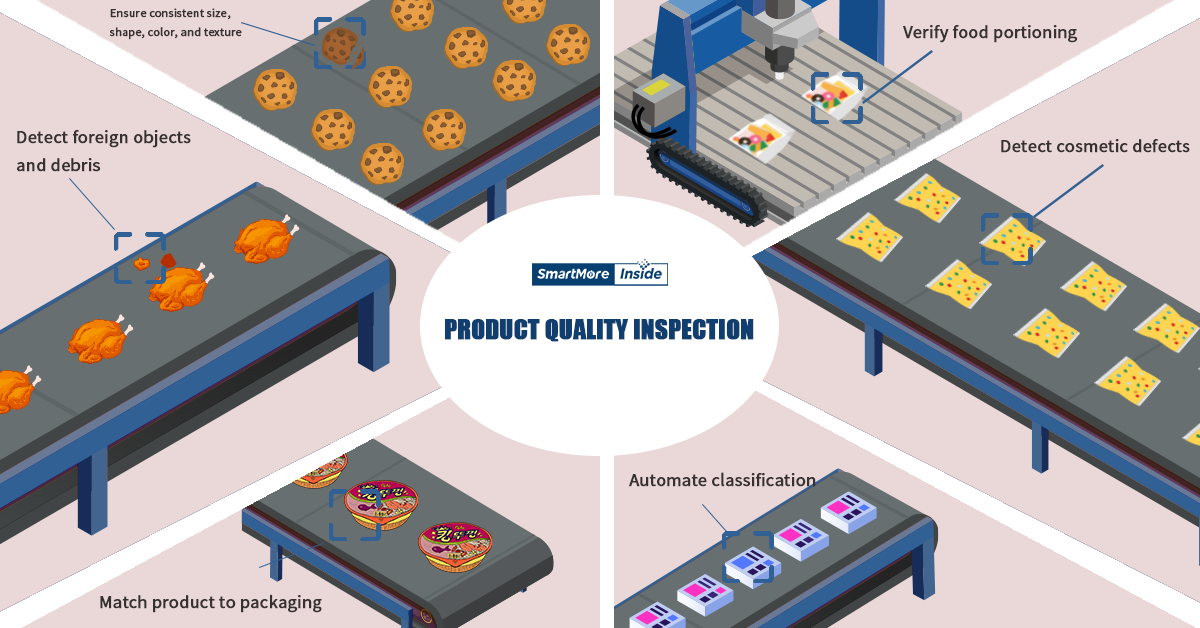

Product quality Inspection

During production, things might break or get damaged. To ensure customer satisfaction and maintain a good brand image, it is essential to inspect the product's quality before packing. Before delivery of goods to the consumers, SmartMoreInside vision systems and industrial barcode scanners can inspect the quality of the products to find any size, shape, color, texture, portioning, and fill level defects. By preventing stoppages and delays, these inspections save your business' reputation from the overall impact of defective goods.

Main Advantages

Packing Inspection

Customers’ perceptions of a product's value, safety, and quality are influenced by its packaging. If a defect or inaccurate labeling in the product packaging goes overlooked, it might have severe effects on the business. To ensure customer satisfaction regarding safety and quality, SmartMoreInside vision systems inspect food packaging to ensure that it is properly put together, free of defects, and complete.

Main Advantages

Food traceability and expiration management

A key problem that raises business risk and undermines consumer confidence in brands is poor traceability. The food sector produces goods intended for human consumption. To assure safety and peace of mind, extreme care and management are important for producers, distributors, and food manufacturers because the incidents of bacterial contamination and other food-borne illnesses are increasing.

In the food sector, legislation is also being implemented. Three capabilities for managing expiry dates have been included in addition to manufacturing date and lot number. It has been systematized for “stock by date”, “ship by date”, and “best by date”.

SmartMoreInside devices ensure traceability including verification of correct labeling, and packing errors, preventing counterfeiting, and verifying product ingredients.

Main Advantages

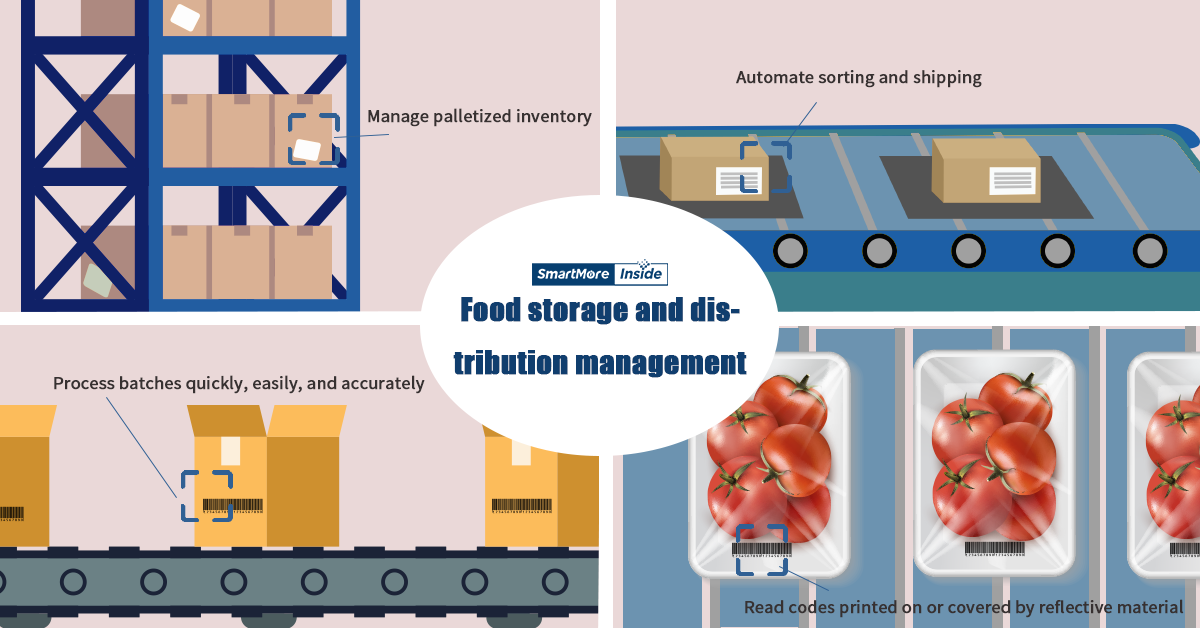

Food storage and distribution management

Food and beverage products are increasingly produced, stored, and shipped from the same facility. To satisfy rising performance standards and consumer demands, manufacturers must optimize not just their production capacity and quality but also their storage and delivery processes. The speed, accuracy, and productivity of warehouses and distribution centers may be significantly increased by using SmartMoreInside vision systems and image-based barcode scanners, which have the one of highest read rates in the market.

Main advantages

SmartMoreInside’s machine vision systems

In terms of inspecting, identifying, and guiding parts, SmartMoreInside machine vision systems are unrivaled. They offer dependable, consistent performance for simple to complicated jobs and are simple to deploy.

https://inside.smartmore.com/products/2D-Camera_gid-57856.html

SmartMoreInside 3D line laser camera series is a professional product for 3D positioning guidance and 3D measurement for high precision. It has high structural strength with an industrial aluminum alloy shell. It is integrally formed and can meet various harsh working conditions. Pre-calibrated before leaving the factory, the calibration file is burned in the camera. While SmartMoreInside 3D line spectrum confocal sensors break through the limitations of traditional detection methods and provide optical precision detection sensors with higher measurement accuracy and faster measurement speed for the industry 4.0 era.

https://inside.smartmore.com/products/3D-Camera_gid-57876.html

SmartMoreInside is committed to providing industry-leading barcode readers to ensure ease in product management and traceability. We offer a variety of 1D and 2D code readers with high flexibility to meet the tough industrial/commercial scenarios to efficiently satisfy the needs of multiple industries including automotive, logistics, food, and packaging, etc., etc. Our code readers are equipped with a high-speed Cortex 4-core processor and Mega-pixel image sensors offering the best of the class and reliable scanning solution for labels and DPM codes on different surfaces.

https://inside.smartmore.com/products/Code-Reader_gid-57869.html

This robotic arm series is developed specifically for materials handling, loading, unloading, packing, sorting, gluing, grinding, polishing, deburring, assembly, inspection, etc. it can be processed in hygiene, humid or harsh environments. These are lightweight, elegant, fast, accurate, and provide excellent performance.

https://inside.smartmore.com/products/Robot_gid-61036.html

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent